Silicon Boats for vertical furnaces

Parts made from CZ monocrystalline Silicon for high temperature processes, annealing and oxidation. For wafer diameters of 150 mm, 200 mm and 300 mm.

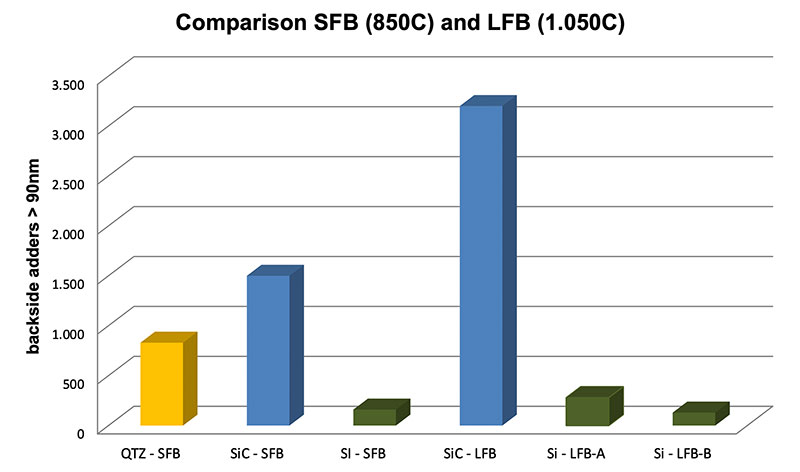

In the past furnace processes used almost exclusively wafer boats made from silicon carbide or quartz glass. Both materials have a different coefficient of expansion compared to the silicon wafer. This always causes friction on the back side of the wafer during the temperature processing, which then causes scratches and other defects.

Depending on the contact surface between the wafer and the boat and the process temperature, induced defects can under certain circumstances, be visible on the frontside of the wafer and hence can influence the yield of the chip in these regions. Defects on the backside of the wafer can at later processing be dislodged and redistributed on the frontside of adjacent wafers thus again causing a yield impact.

By using silicon boats (identical expansion coefficient to silicon wafers), this friction is prevented or sigficantly reduced.

The use of silicon boats significantly (proven by multiple evaluations) reduces the number of defects on the wafer backside. The same applies to the slip lines and imprints on the wafer front.

These technical improvements can lead to higher chip yields on the wafers, which has already been proven by several customers as part of successful product qualification.

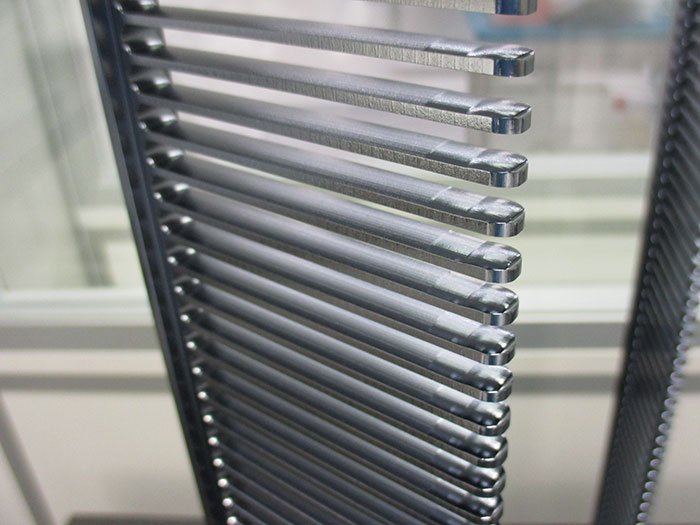

Depending on the application / process, different designs of the boat contact area (where wafer contacts boat) may become necessary. CE-MAT has experience with different applications and optimized design.

The silicon boats supplied by CE-MAT are made exclusively from high-purity CZ monosilicon. By using the monosilicon with the identical purity of wafers, contamination (especially heavy metals) is prevented. After manufacturing, the boats are finally cleaned and packed in a class 100 clean room.

The boats can then be used directly at the customer without additional cleaning, however a pre-conditioning routine must be performed on the boats before finally using in the customer’s production process.

The recommended pre-conditioning process is provided with the boats.

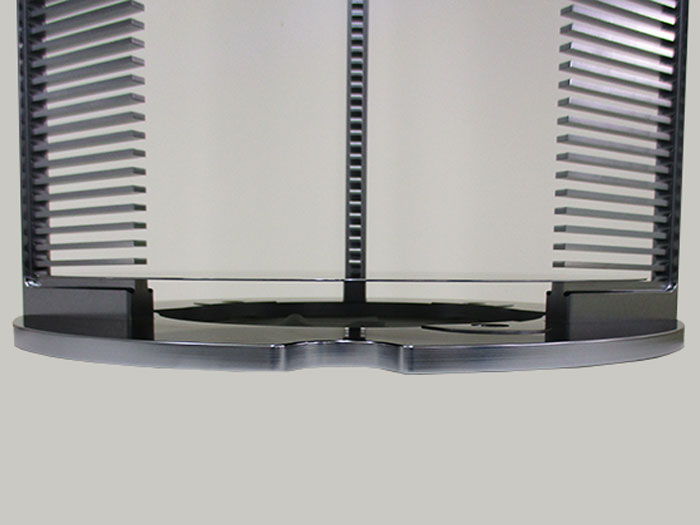

The silicon boats are manufactured in separate parts:

i.e. Top and bottom plates and the rods with fingers which contact the wafer. Assembly of the parts is easy and happens in the customer’s location.

Module production makes it possible to modify the boats. In particular, increasing the number of slots makes it possible to increase the capacity for a process by 15-20%.

It is also possible, if necessary, to save a new investment in further furnaces when equipping several existing vertical furnaces with the capacity-enhanced silicon boats from CE-MAT.

Another key advantage is the short delivery time of the CE-MAT silicon boats.

The current delivery time for a silicon boat depending on the type and complexity is a maximum of 12 – 14 weeks. The delivery time for SiC boats may be> 52 weeks.

| Feature | Silicon boat | SiC boat | Comments for Silicon boats |

|---|---|---|---|

| Purity | +++ | + | wafer like CZ Mono silicon |

| Surface roughness | ++ | o | Ra < 1 µm |

| Repair | ++ | o | Exchange of one rod possible |

| Backside defects | ++ | – | up to 10-times less defects on wafer backside |

| Backside damage | ++ | – | 10-times less scratches on wafer backside |

| Front side damage | ++ | o | no imprints on front side, no defocus issues |

| Front side particles | ++ | o | 2-times less particles |

| Wafer contact | Optimized contact between wafer and boat for each process and temperature | only standard versions availbable | optimized wafer contact by special design of fingers, less particles, scratches and slip lines |

| Lead time | 2 – 3 month | 1 – 1,5 years | shorter lead times for Si boats possible |

CE-MAT provides a special version of the short finger boats – Sikle boats with removable wafer holders. The possibility of changing single sikle segments an ernormous cost saving potential is generated. In addition individual assembling oft he sikles ispossible.